Building the Aro Lineage monumental phurba

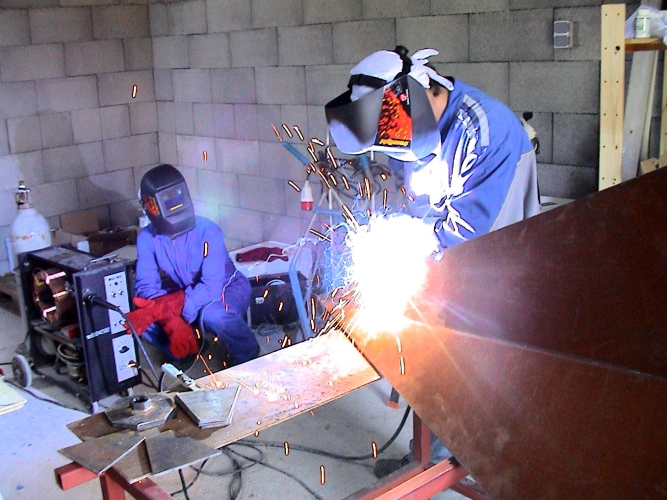

The steel work – the blades

With the work for foundation and base completed, Ngakpa Trögyal and Georg retreated to the forge house to start with steel work again. Firstly they finished off the edges of the blades, welding them tightly and grinding the welds neatly. A central reinforcement had to be welded into the blades to support the haft of the phurba.

The base of the blades had been cut out by plasma, and therefore the raw blades did not at first dsplay the elegant curve of the phurba’s blades. Several hours of precise and neat grinding were required to shape the blades accordingly. After ‘curving’ the bases they were closed with steel sheets using the old boilermaker’s technique of hammering the welds as long as they were still glowing red. This hybrid technique between forging and welding allowed smooth curves to be made. A window in each blade was left open to serve as access for the rabné (rab gNas – ceremony of consecration).